About Design to Product's CNC Services

We make accessing global manufacturing technologies easy and reliable. Connect with our network of certified producers for all your manufacturing needs.

Our digital platform streamlines sourcing with AI-powered instant quotes and seamless order management. We support projects from prototyping to full-scale production.

We partner with a wide network of trusted production teams across Europe and globally, giving customers access to over 3,000+ printers and machines

Our trusted supplier network spans Europe and the globe. After you place an order, we match you with the perfect production partner equipped to start your project right away.

D2P CNC's Pricing

Prices vary based on quantity, material, and technology, with transparent pricing provided in your quote. Our one-stop-shop platform for on-demand manufacturing offers free use and online cost estimates. You only pay for part production and shipping.

After placing an order, view real-time delivery costs based on your shipping address.

Currently, pay via bank transfer within 30 days of receiving the invoice or by credit or debit card. For other payment methods, please contact us.

Our platform provides instant estimates for cost and delivery time within seconds. Manual cost estimates are typically provided within 24 hours upon request.

D2P CNC's Specs

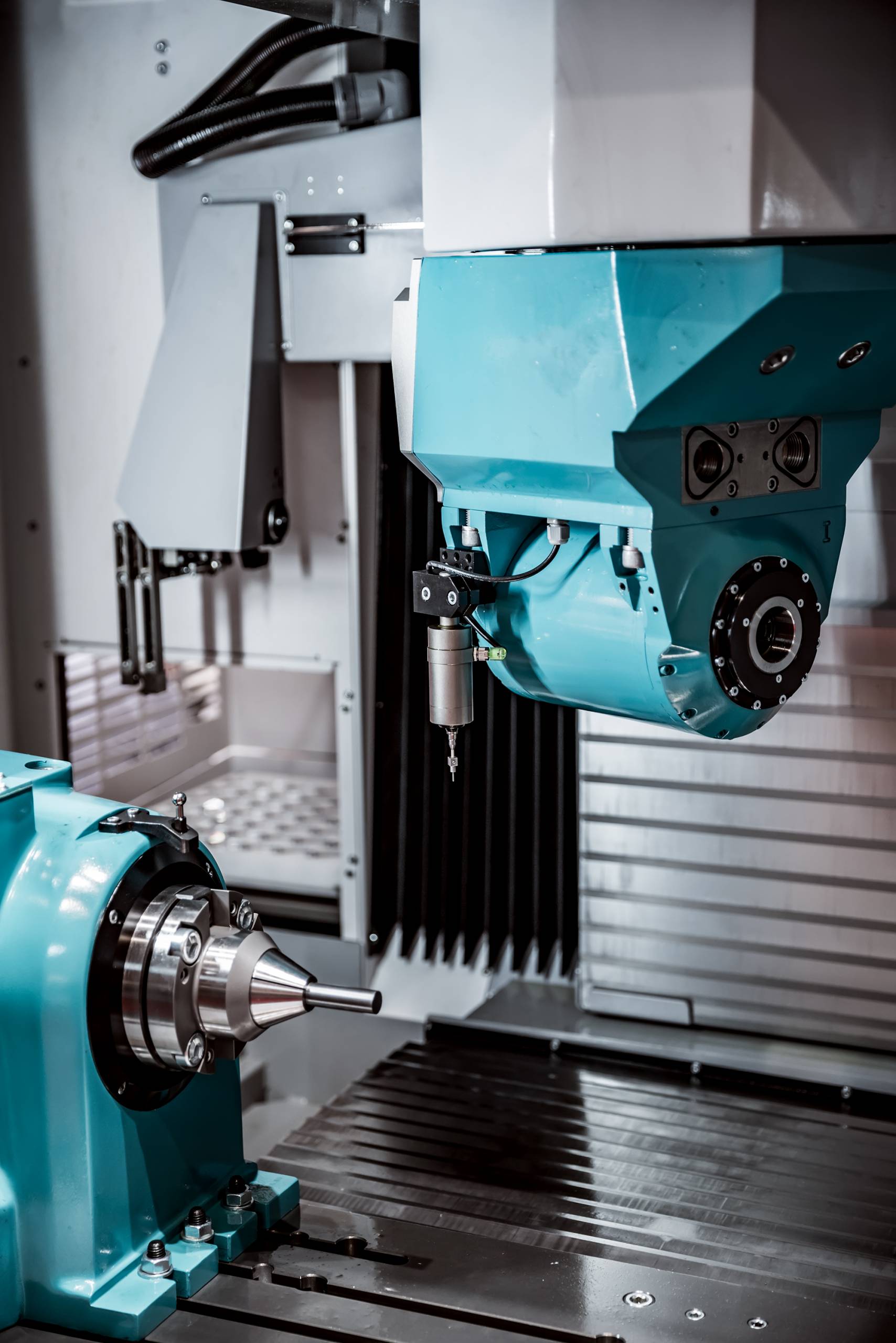

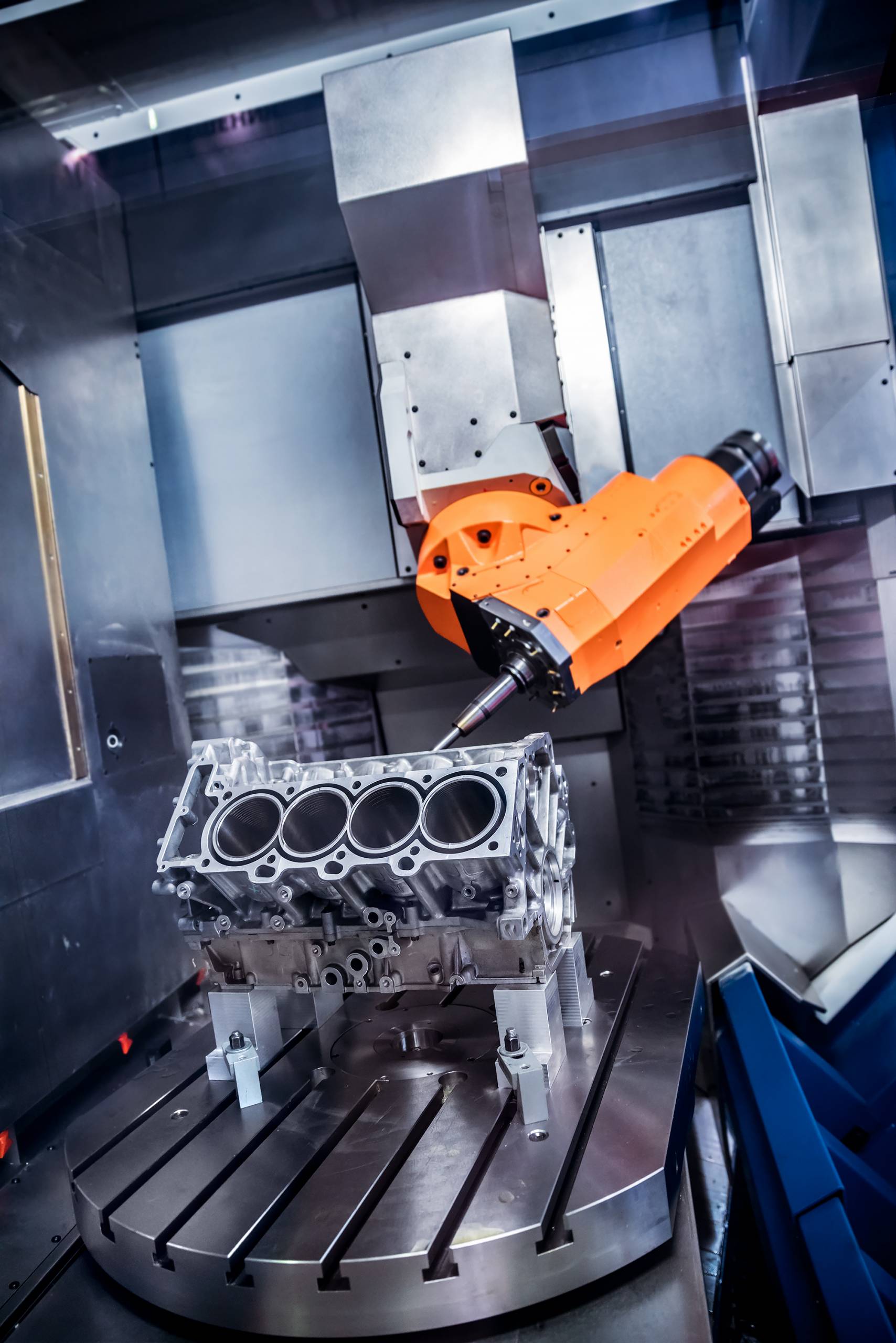

Our network of certified partners allows us to offer a wide range of manufacturing technologies, including the popular CNC machining for precise milling, turning, and drilling.

Soon, we’ll also be offering:

- Laser Powder Bed Fusion (L-PBF): Ideal for creating complex, stable metal parts using a laser to melt metal powder.

Selective Laser Sintering - (SLS): Similar to L-PBF but for polymers, this method produces highly accurate parts.

- Multi Jet Fusion (MJF): This layer-by-layer process builds parts quickly and accurately with a high output.

Fused Deposition - Modeling (FDM): A cost-effective and scalable method that uses a heated nozzle to produce thermoplastic parts efficiently,

We manufacture parts from a wide range of polymers and metals, depending on the technology used. Popular materials include Scalmalloy©, Aluminium AISi10Mg, CuNi2SiCr, CuCP, Tooling steel MS1 (1.2709), Stainless steel 316L (14404), Hastelloy© X, Inconel 718, Inconel 625, PA11, PA12, PA12 Glass Filled, PA12 Al Filled, PA12 Flame Retardant, TPU, Polycarbonate, PC-ABS, and ULTEM© 9085. We regularly add new materials.

Our platform supports all files, with the most popular being 3DXML, 3MF, ACIS, CATIA V4, CATIA V5, DXF, DWG, IGES, Inventor, JT, NX, OBJ, Rhino, Solid Edge, SolidWorks, STEP, STL, VDA, 3DS, XCGM, WRL, CTM, Draco, PLY.

Yes, we ensure quality in several ways. Our supply chain consists of carefully selected partners who go through a thorough selection and onboarding process. We continuously monitor and assess them to keep up with engineering best practices and technological advancements. Our highly trained engineers review and inspect every part ordered through our platform, providing detailed inspection reports. All our manufacturing partners are ISO9001 certified. We guarantee material properties based on our data sheets and standardized industrial inspection processes, and we also offer additional quality inspection reports in partnership with ZEISS.

We take your intellectual property very seriously.

Every drawing, sketch, or picture uploaded to our system is securely stored using state-of-the-art security algorithms. Once your order is placed, only the manufacturing partner assigned to your part can access the drawing. All manufacturers in our network are contractually obligated to safeguard your IP.

Furthermore, we maintain rigorous cybersecurity standards, including European-only AWS servers, advanced antivirus software and firewall protection, and regular cybersecurity training and awareness programs.

You’ll receive the expected delivery date with every quote.

The full manufacturing process, from order to delivery, varies based on part complexity, manufacturing partner, and production technology. We strive for the fastest turnaround possible, aiming to deliver within the quoted timeframe.