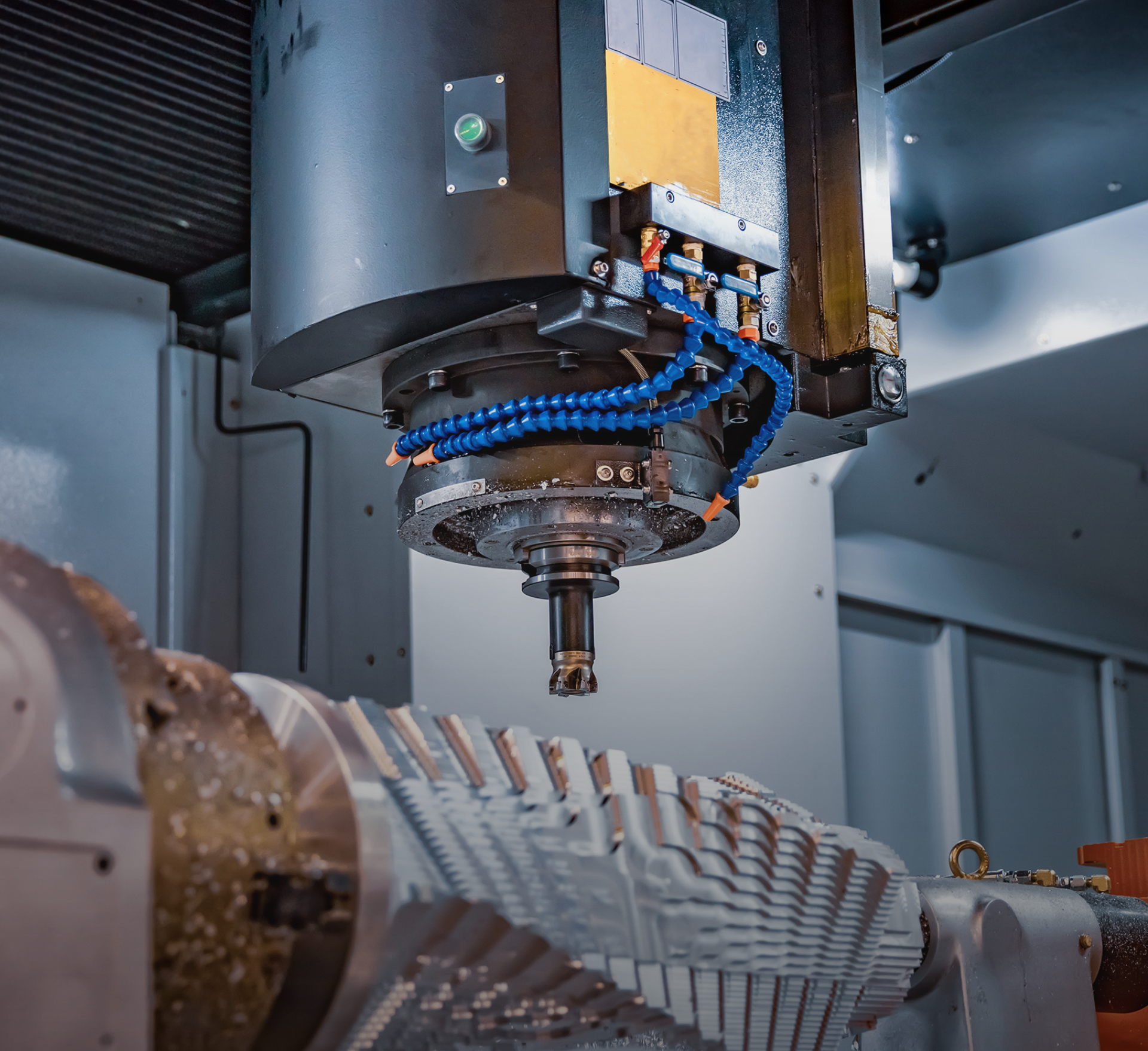

CNC milling is a highly accurate machining process that employs multi-point cutting tools to shape parts from nearly any material, ensuring top-notch surface finishes. This versatility makes it suitable for a wide range of applications, from intricate prototypes to robust industrial components.

Beyond precision, CNC milling is an efficient technology offering quick lead times and high-volume production capabilities. Its ability to rapidly produce consistent, high-quality parts makes it a valuable asset in modern manufacturing.

How CNC Milling Works

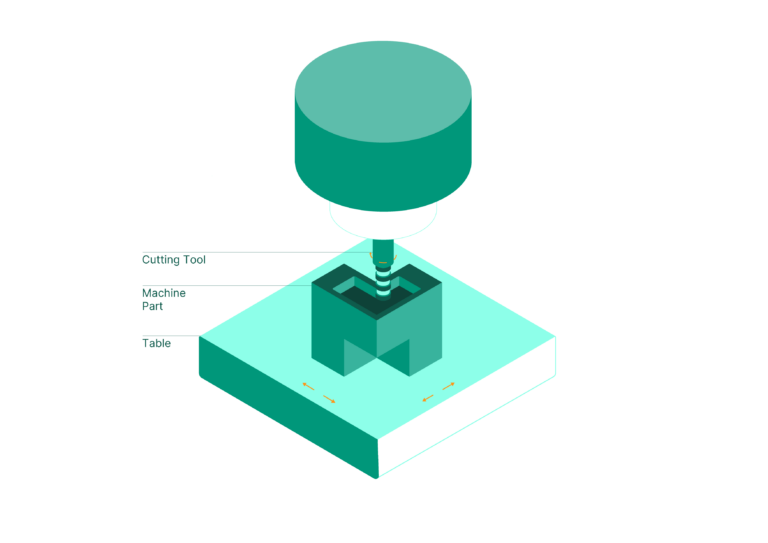

Milling is one of the most widely used processes in subtractive manufacturing. It involves a rotary cutting tool with a geometrically determined edge, which can be categorised into face milling and peripheral milling.

Face milling utilises a vertical cutting axis to process frontal areas and cavities, making it ideal for flat surfaces. In contrast, peripheral milling employs a horizontal cutting axis, perfect for creating deep slots and threads.

.

CNC Milling Use Cases

CNC milling is a versatile manufacturing process suitable for everything from prototyping to series production. Its high accuracy and excellent surface finishes ensure consistent quality and short lead times. This technology is particularly beneficial for parts with numerous features, such as drilled holes, due to its precision and repeatability.

| CNC Milling by the Numbers |

|---|

| Max Build Size: 2000 mm x 800 x 1000 mm (Standard) Lead Times: Starting at 6 days Minimum Wall Thickness: 0.2 mm (depending on material and geometry) Dimensional Accuracy: ISO 286 Tolerance grade 7 (0.015 mm for a 6mm diameter) |

Key Feature: Diverse Range of Materials

CNC milling accommodates a wide range of materials, including metals and polymers, each offering unique properties such as strength, durability, heat resistance, and electrical conductivity. These materials can be tailored to meet specific application requirements.

This versatility allows you to select the most cost-effective material for your projects, ensuring optimal performance without compromising budget.