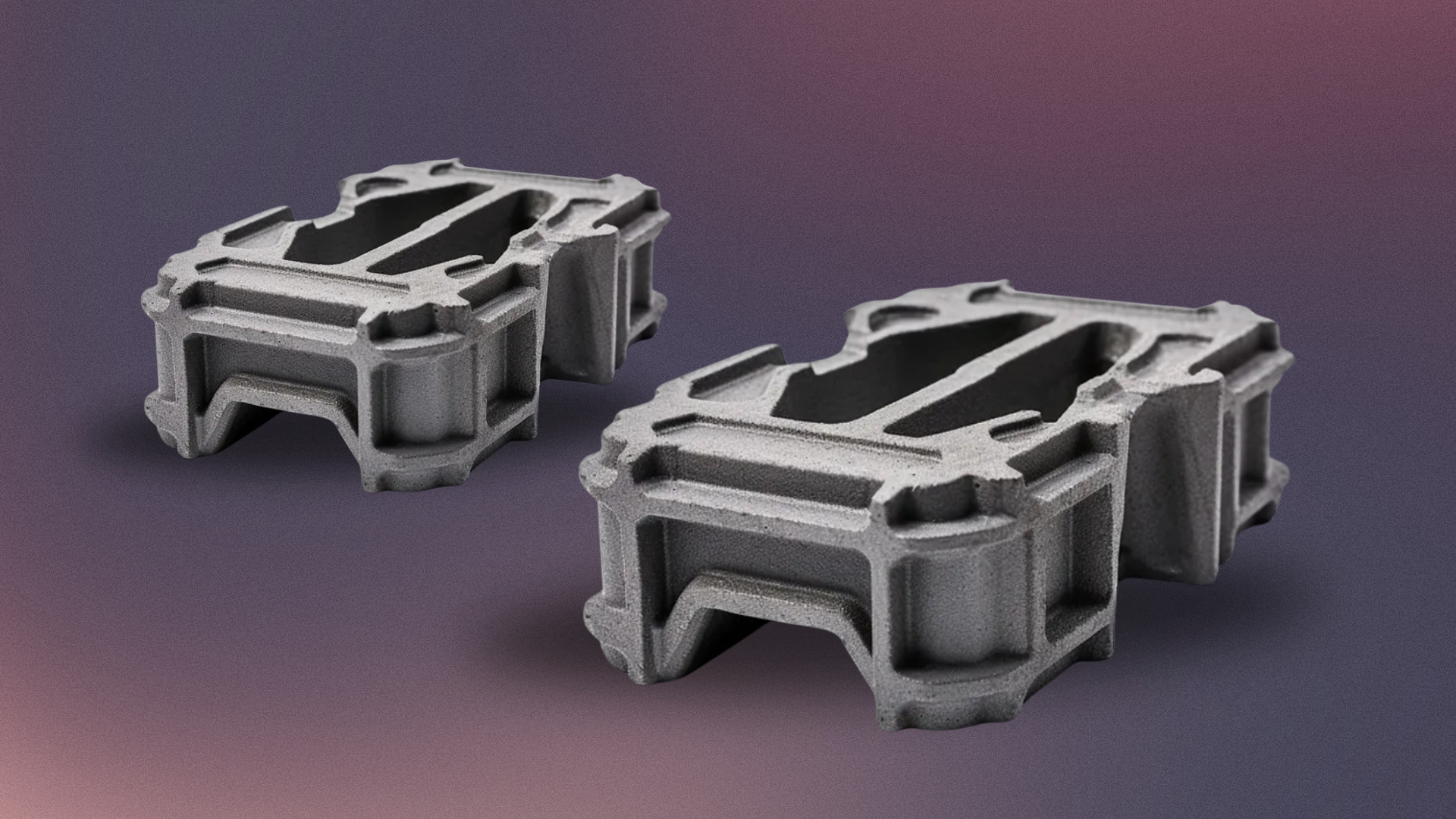

Rapid casting brings together the best of traditional craftsmanship and cutting-edge 3D printing technology. By using 3D-printed molds, we can create intricate designs with precision, while keeping costs low. This innovative approach is perfect for producing unique, one-off parts that require both detail and affordability.

D2PCNC revolutionizes rapid casting with advanced technology, speeding up production and cutting costs. We deliver high-quality, intricate components quickly, whether for custom one-offs or large runs, without sacrificing precision.

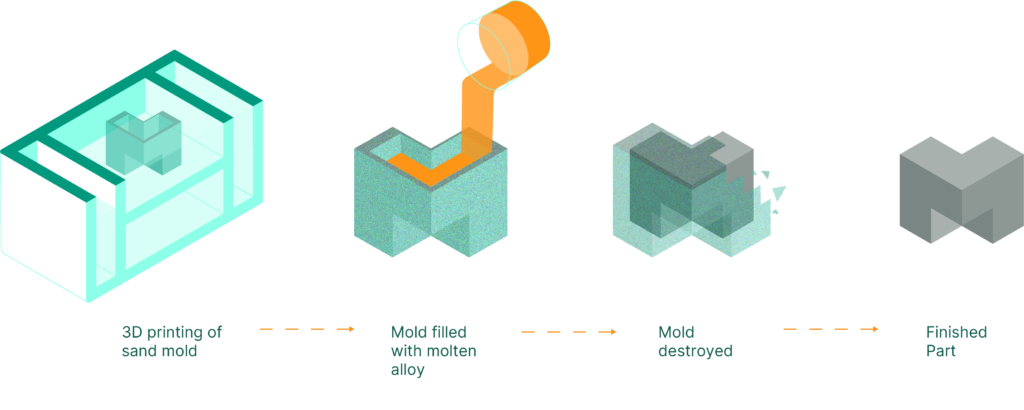

How Rapid Casting Works

The first crucial step in the process is 3D printing the mold using sand. At D2PCNC, we make this easy for you by handling the design and printing. Just send us your design file, and we’ll take it from there, crafting a high-quality sand mold tailored to your specifications. You can sit back and relax while we ensure everything is set for your project to move forward smoothly.

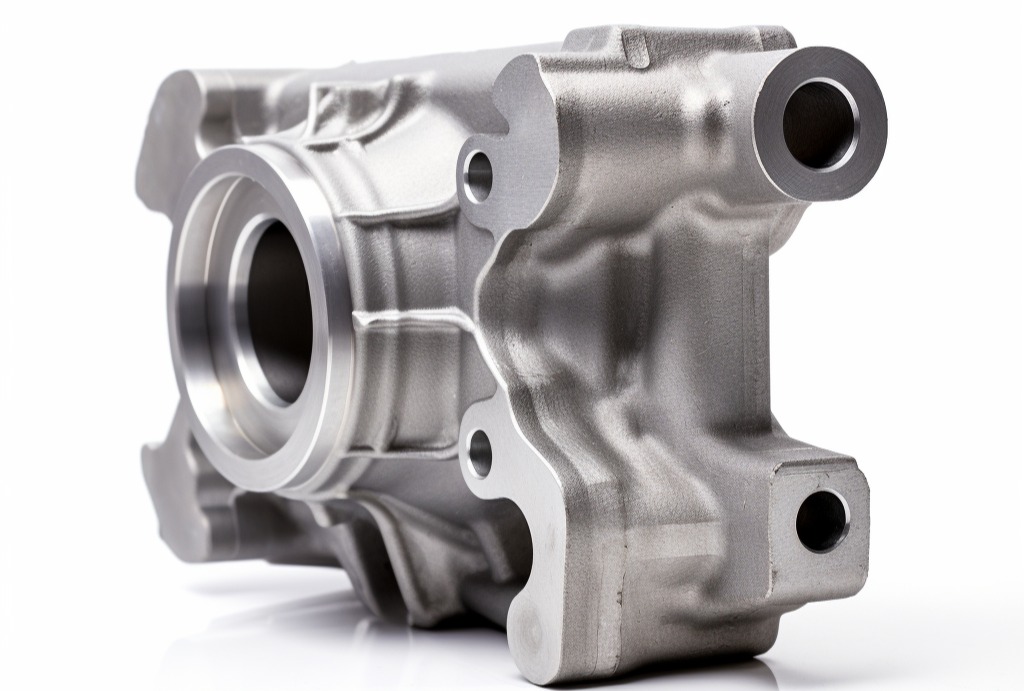

The additive manufacturing process excels at producing molds with complex internal cavities and intricate geometries. Once your sand mold is complete, we pour molten metal into it. As the metal cools, it solidifies, and the sand mold is then carefully broken away to reveal the finished part.

Following this, our engineering experts conduct a thorough quality inspection to ensure your part meets all your specifications. You’ll receive your precisely crafted component, ready for use, and reflecting the highest standards of craftsmanship.

Rapid Casting Use Cases

Rapid casting offers a significantly lower initial investment compared to traditional casting methods. This affordability, along with its flexible tooling and ability to handle complex designs, makes it an attractive choice for various applications:

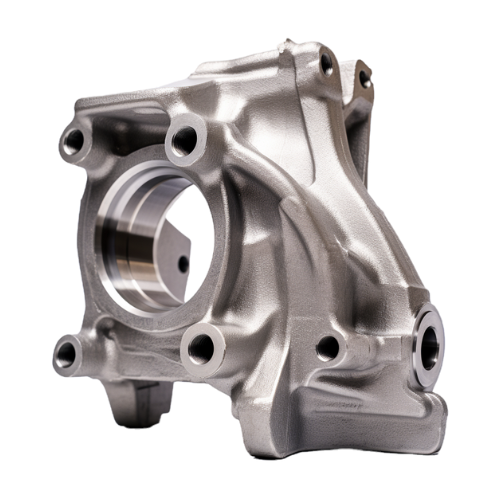

After-Market Parts: Reproduce parts when the original mold is no longer available, avoiding the high costs and extensive engineering typically required for other manufacturing methods.

Cost-effective Prototypes: Create low-cost prototypes that can be seamlessly transitioned to traditional sandcasting for final production.

On-Demand Spare Parts: Supply spare parts across diverse industries, including maintenance, industrial machinery, automotive, infrastructure, and oil & gas.

| Rapid Casting by the Numbers |

|---|

| Max Build Size: 1000 mm x 540 mm x 400 mm (Standard) Lead Times: Starting at 20 days Minimum Wall Thickness: In accordance with ISO 8062 |

Key Features:

Oversized Parts

Looking for larger parts? You’ve come to the right place.

While our standard rapid casting parts are typically up to 1000 mm in the longest dimension, we can accommodate larger sizes upon request for specific geometries and parts.

With these extended capabilities, the possibilities for your projects are endless. Simply upload your part and detail your requirements, and our team of experts will guide you through every step to bring your vision to life.