Vacuum casting is a highly effective manufacturing technique known for its precision and accuracy. It provides a cost-efficient solution for creating prototypes, specialized parts, and small production runs. This method ensures detailed and accurate results, making it ideal for a range of applications where quality and detail are paramount.

D2PCNC revolutionizes vacuum casting by integrating advanced technology to enhance both speed and cost-efficiency. We deliver high-quality, intricate components rapidly, whether for custom one-offs or larger production runs, all while maintaining exceptional precision. With D2PCNC, you get the best of both worlds: advanced technology and meticulous craftsmanship

How Vacuum Casting Works

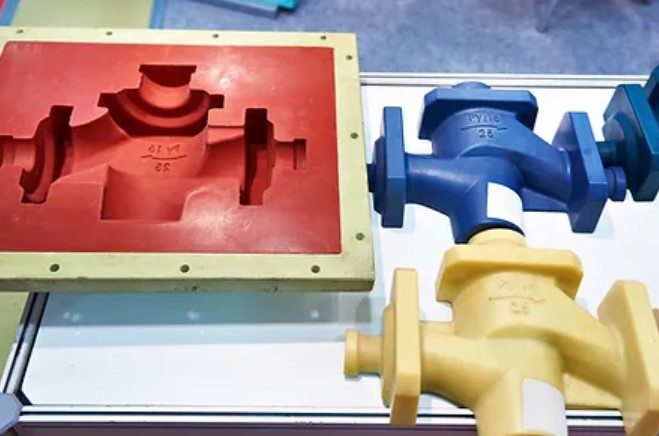

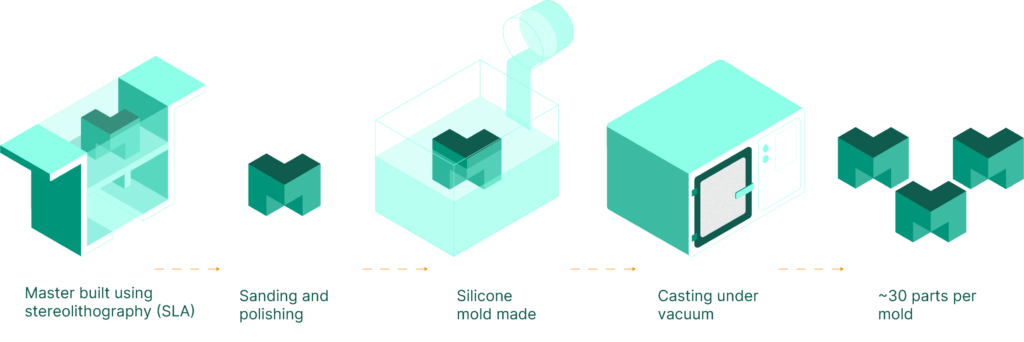

A 3D-printed master model is first placed in a container and covered with liquid silicone rubber. The container is then put into a vacuum chamber, where the silicone forms a detailed mold around the model.

Next, liquid material is poured into the mold cavity and placed under vacuum to eliminate any air bubbles. The material is left to harden, solidifying into the desired shape.

Once hardened, the mold is opened, and the replica is removed. This process can be repeated up to 30 times per mold, efficiently and easily producing multiple parts.

Vacuum Casting Use Cases

Vacuum casting is a highly efficient method for small-batch production, offering a cost-effective and rapid alternative to traditional manufacturing techniques. This process is ideal for scenarios where production numbers are low, providing a practical solution for creating limited runs of high-quality components without the extensive costs associated with injection molding.

The technique involves creating a detailed silicone mold from a 3D-printed master model, which is then used to cast liquid materials. This approach allows for the production of precise and intricate parts, making it particularly suitable for prototypes, specialized components, and custom designs.

In addition to its efficiency, vacuum casting is renowned for its smooth finish and wide range of available colors. These attributes make it an excellent choice for producing high-quality end-use parts that require both aesthetic appeal and durability, ensuring that the final products meet stringent standards for both function and appearance.

| Vacuum Casting by the Numbers |

|---|

| Max Build Size: Up to 500 mm Lead Times: Starting at 9 days Minimum Wall Thickness: 0.5 mm (material/geometry dependent) Standard Color: Any, as color can be mixed in the resin before production Dimensional Accuracy: As accurate as +/- 0.1% |

Source Industrial-Grade Vacuum Casted Parts

D2PCNC offers unparalleled flexibility in sourcing parts to meet your specific needs. With instant quotes and streamlined ordering through on-demand manufacturing, you can efficiently manage your parts procurement. Our team of experts is dedicated to supporting both large and complex orders, collaborating closely with you to develop, align, and oversee a comprehensive quality plan from start to finish. This ensures that every aspect of your manufacturing process is handled with precision and care.

On-Demand Manufacturing

- Instant quoting and DFM checks

- Short lead times

- Fast and intuitive order placement

Production Orders

- Expert support from end-to-end

- Comprehensive manufacturing and quality plan

- Guaranteed quality meeting advanced specifications

Popular Vacuum Casting Materials

Vacuum casting provides a diverse selection of resins that mimic the properties of thermoplastics used in other manufacturing methods. These resins are designed to offer similar performance and characteristics, making them versatile for various applications. Some of the most popular options include:

| Popular Vacuum Casting Materials |

|---|

| ABS-like: Acrylonitrile butadiene styrene (ABS)-like material combines strength and durability with low weight and a high load capacity. The material provides a good compromise between mechanical properties, cost, and accuracy. Thanks to its versatility and affordable price, it’s widely used across industries. ABS-like is often used for functional prototypes, consumer products, and industrial parts such as components and housings. PC-like: Polycarbonate (PC)-like combines good mechanical properties such as impact resistance, strength, rigidity, and hardness. It also offers temperature with high dimensional stability and heat resistance. PC is typically used for jigs and fixtures, cases of any kind, and visual models. PP-like: Polypropylene (PP)-like offers high strength and toughness combined with a light weight. This material also has low moisture absorption. PP-like is a relatively inexpensive material often used in everything from electronic components to everyday household goods, such as storage containers. TPU: Thermoplastic polyurethane (TPU)-like offers advantages in terms of elasticity, flexibility and durability. The material is ideal whenever shock absorption is required. TPU is often used for prototyping flexible parts, such as seals and gaskets. Another specific use case is for shock-absorbing parts, such as shoes and protective sports gear. |