Multi Jet Fusion (MJF) is a cutting-edge additive manufacturing technology known for its precision and efficiency. It stands out for its ability to produce high-quality parts with excellent mechanical properties at a rapid pace. The process leverages a sophisticated approach to layer-by-layer production, enabling short lead times while maintaining high output volumes. This makes MJF an attractive choice for both rapid prototyping and functional end-use parts.

In addition to its speed and accuracy, MJF offers a cost-effective solution for producing durable components. The technology’s efficient use of materials and streamlined production process contribute to lower part costs, making it a preferred option for projects that require both high performance and economic feasibility. Whether for prototypes or final products, MJF delivers a compelling balance of quality and affordability.

How MJF works

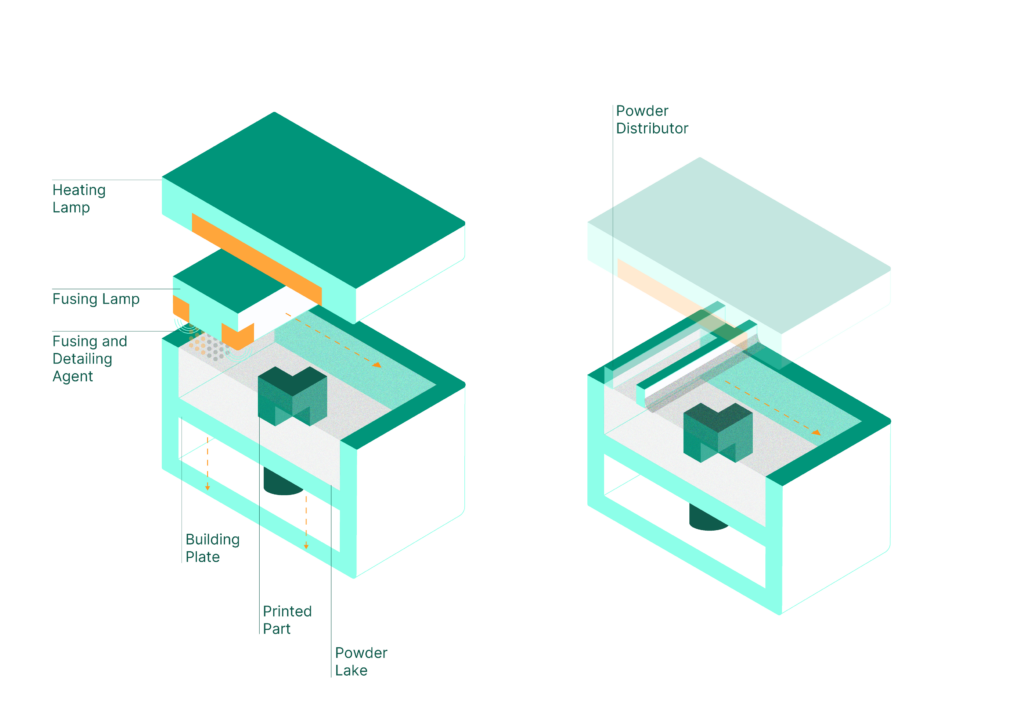

Multi Jet Fusion (MJF) is a sophisticated powder bed fusion technology that constructs parts layer by layer. The process begins with a movable unit that evenly spreads a thin layer of thermoplastic powder across the build platform. An orthogonally moving unit, equipped with infrared lamps and a dosing system, then follows. The first lamp preheats the powder bed to just below its melting point, which is a key difference from other additive manufacturing methods that rely on high-energy lasers.

Once preheating is complete, the system applies fusing and detailing agents to the powder bed. The fusing agent is applied to areas where fusion is required, enhancing the powder’s absorption of infrared radiation. A second infrared lamp then heats these areas, causing the powder to melt and fuse with the underlying layer. This process not only bonds the powder layers but also results in a characteristic grayish tint on the finished parts. The detailing agent, applied simultaneously, evaporates during the heating process to prevent excess powder from fusing onto the contours, ensuring sharp edges and precise dimensional accuracy.

After each layer is completed, the process repeats for the subsequent layers, building the part up in a meticulous and controlled manner. This layer-by-layer approach ensures high-quality results and enables the production of complex, detailed components with excellent mechanical properties.

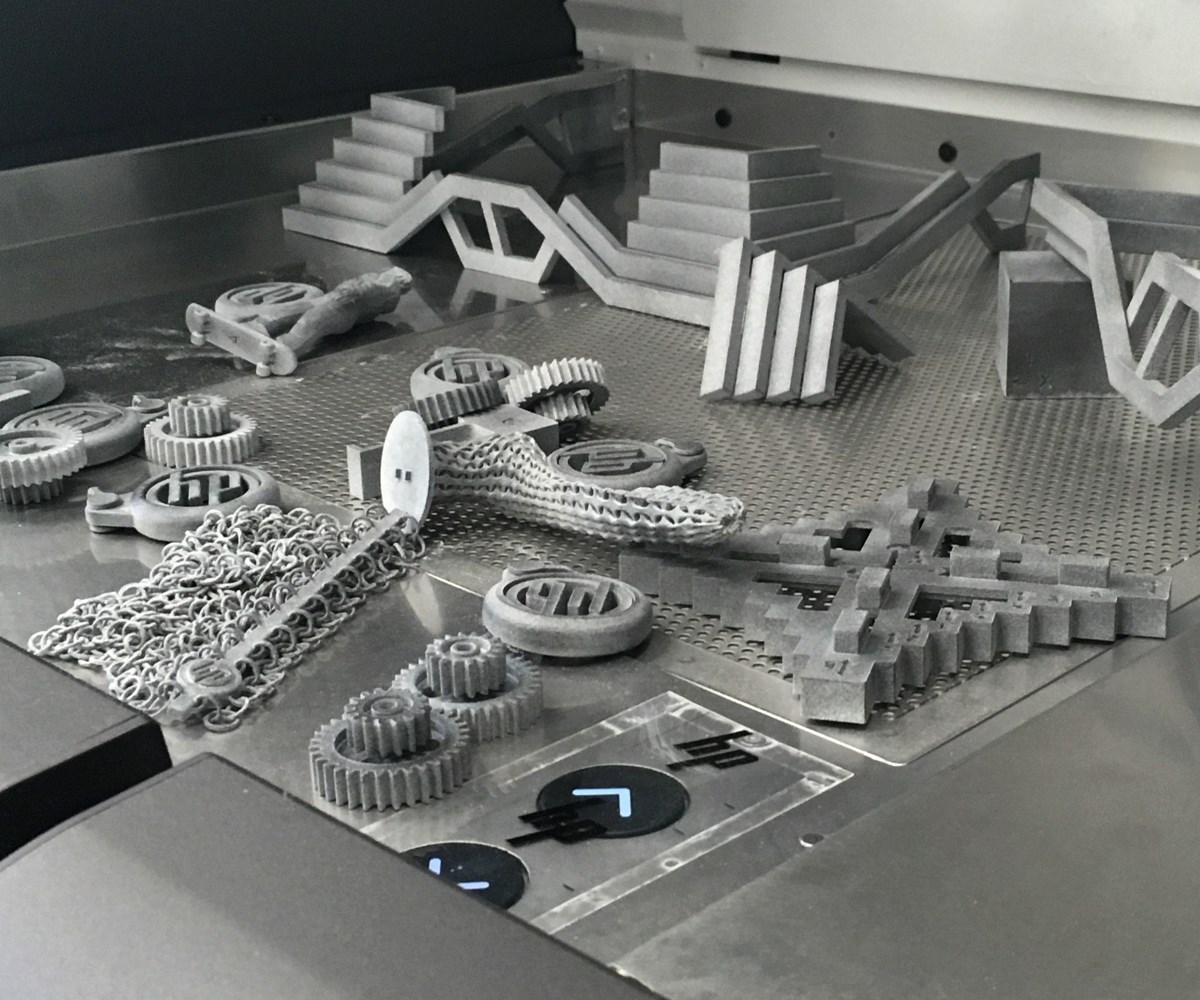

MJF Use Cases

Multi Jet Fusion (MJF) is a versatile technology commonly employed for both prototypes and functional prototypes. It excels in applications requiring robust mechanical properties, such as prototypes for injection molding parts or parts designated for rigorous testing. MJF also delivers high-quality end-use components, with the added benefit that unused powder can be partially recycled for future production cycles.

In addition to its general applications, MJF is particularly well-suited for industries requiring biocompatible materials. Consequently, it is frequently used in the production of orthotics and prosthetics, where its ability to produce precise, durable parts is essential for medical applications.

| MJF by the Numbers |

|---|

| Max Build Size: 380 X 284 X 380 mm Lead Times: Starting at 7 days Minimum Wall Thickness: 0.8 mm (material/geometry dependent) Standard Color: Gray Dimensional Accuracy: +/- 0.5% with a minimum of 0.3 mm |

Available MJF finishes

Sanded

Using sandpaper, the sanding process smooths the part and removes any visible blemishes, such as support marks or blobs. The choice of sandpaper grit depends on the layer height and the desired print quality.

Painted

Additional color is applied to the printed part, typically using a professional spray-painting system. To achieve the desired finish, the part undergoes thorough preparation, including precise cleaning and the application of a clear coat.

Smoothed

In the smoothing process, a chemical reaction reworks the plastic component by dissolving its top layer in a solution bath. This results in a very smooth surface, enhancing the overall finish of the part.

Tumbled

Parts are reworked using grinding media in a container, where they undergo deburring, fine grinding, and polishing through the vibration or rotation of the container. This process smooths the surfaces and enhances the overall finish, ensuring the parts are ready for their intended application.

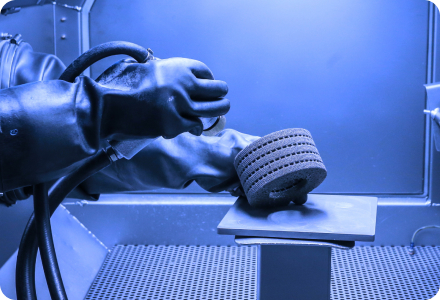

Blasted

An abrasive medium is applied to the component under high pressure, allowing for both functional and aesthetic finishing. Depending on the desired outcome, different media such as corundum, sand, or glass beads can be used to achieve specific surface roughness or to polish the surface for a refined appearance.

Color dyed

The plastic component is immersed in a water bath, triggering a chemical reaction that allows the dye to penetrate deeply. This process creates a uniform colour gradient and results in a more scratch-resistant, durable surface.

Source Industrial-Grade MJF Parts

D2PCNC gives you the flexibility to source parts however you need. Get instant quotes and quickly order parts with on-demand manufacturing. For sophisticated orders, our team of experts will work with you to develop, align, and supervise a manufacturing quality plan from start to finish.

On-Demand Manufacturing

- Instant quoting and DFM checks

- Short lead times

- Fast and intuitive order placement

Production Orders

- Expert support from end-to-end

- Comprehensive manufacturing and quality plan

- Guaranteed quality meeting advanced specifications

Popular MJF materials

Not sure which material is best for your project? Use our interactive technology and material advisor to explore and find the ideal solution tailored to your needs.

| MJF by the Numbers |

|---|

| PA 11: PA 11, used in the MJF process, is known for its high elongation at break of up to 40% and excellent impact resistance, making it ideal for mechanically stressed parts requiring high flexibility. Made from renewable raw materials and biocompatible, PA 11 is approved for skin contact, making it suitable for applications such as functional prototypes and lower limb prosthetics. Lead time is 7 days. PA 12: PA12 is a versatile material that processes efficiently in the Multi Jet Fusion (MJF) process, offering cost-effective production and high reusability of used powder. It boasts excellent mechanical properties and chemical resistance, particularly against oils and greases, making it ideal for functional parts. Typical use cases include functional prototyping and the production of prosthetics and orthotics. Lead time is 7 days. TPU: TPU is a flexible elastomeric material ideal for producing parts with high elasticity and shock absorption through the MJF process. This combination allows for significant design freedom, making it perfect for applications requiring flexibility and durability. TPU is commonly used in robotic clamps, elastic covers, folding bellows, and energy-absorbing components like helmets, where accident prevention is crucial. Lead time is 9 days. |