Stereolithography (SLA) is a highly versatile 3D printing technology renowned for its precision and ability to realise complex designs. As one of the leading resin-based 3D printing methods, SLA excels in producing detailed and intricate parts with a smooth finish. Its ability to handle fine details makes it ideal for applications requiring high accuracy and fine resolution.

In addition to its design capabilities, SLA offers a cost-effective solution for high-quality prints. The technology’s combination of affordability and superior mechanical properties ensures that it remains a popular choice for both prototyping and final product manufacturing. With SLA, you can achieve both intricate design and functional reliability, making it a valuable tool in various industries.

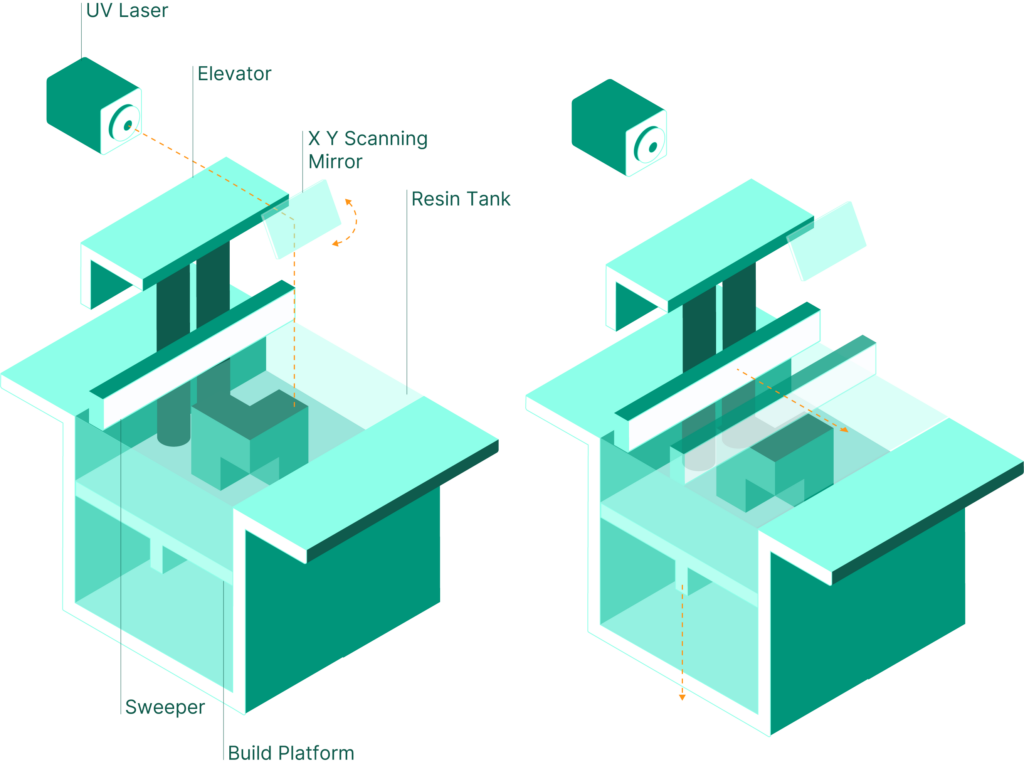

How SLA Works

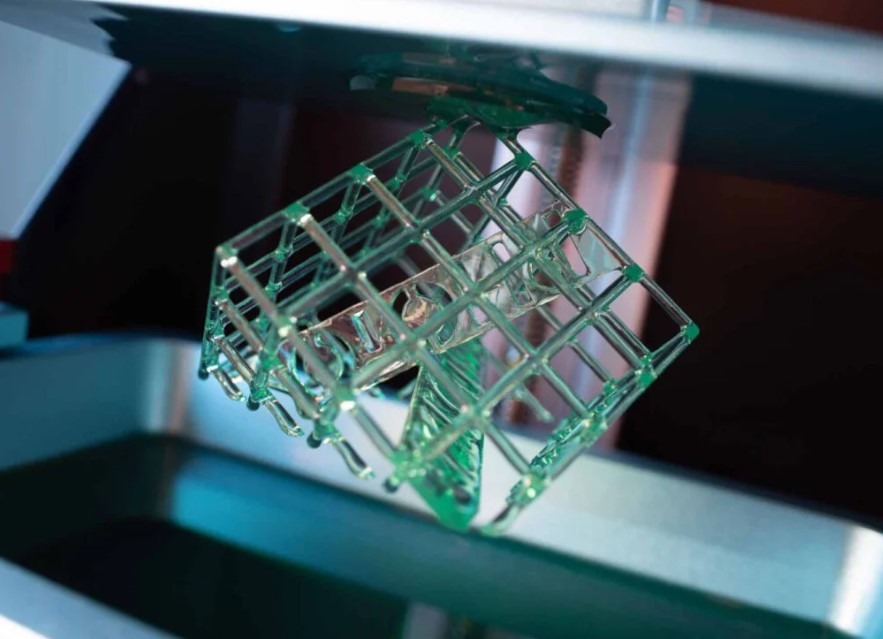

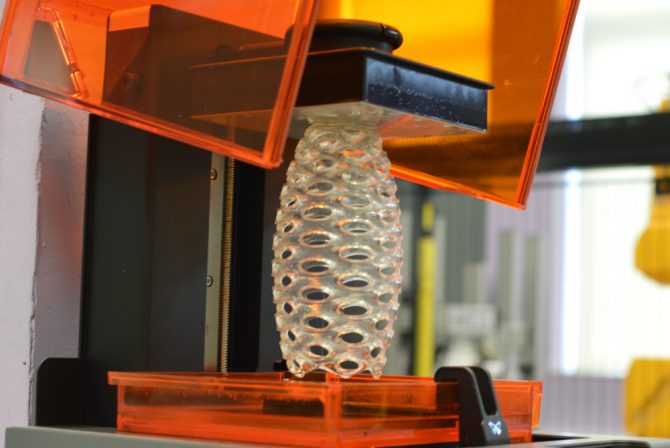

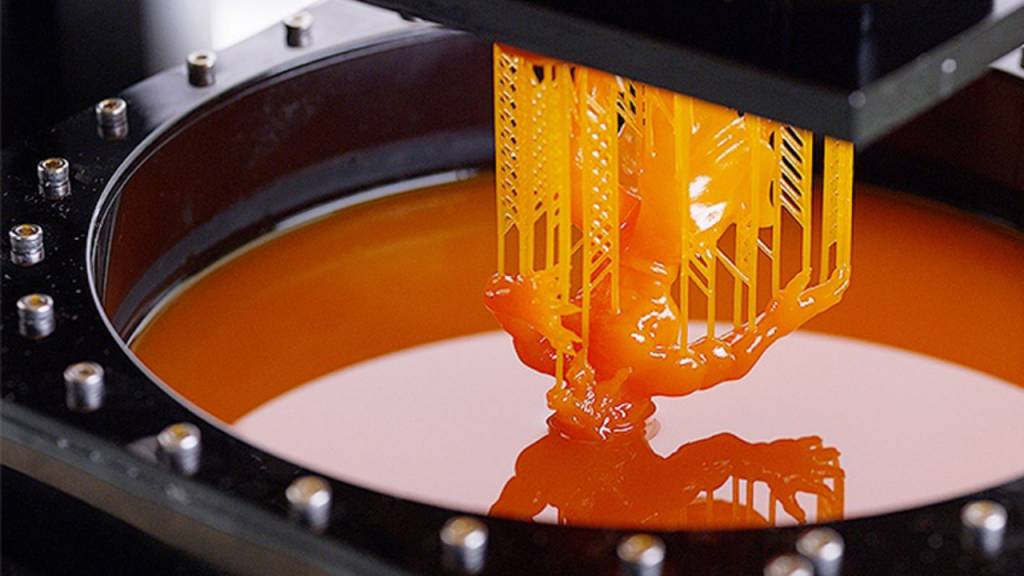

Stereolithography (SLA) operates on the principles of photopolymerization, where a liquid resin is selectively cured by UV light. The process starts with a vat of this liquid resin, which is solidified one layer at a time by a precise UV light source. As the UV light shines onto the resin, it causes the liquid to harden according to the desired pattern.

The build platform then gradually moves, allowing each new layer of resin to be cured and fused with the previous layer. This meticulous layering process ensures the production of highly accurate and intricately detailed parts, all with exceptionally smooth surface finishes. The result is a high level of precision and quality that makes SLA a preferred choice for applications requiring fine details and smooth aesthetics.

SLA Use Cases

Stereolithography (SLA) is widely utilised across numerous applications, including product design, functional prototyping, and even end-use parts. Its precision and versatility make it ideal for creating highly detailed prototypes that are crucial for thorough testing and validation.

This technology enables rapid design iterations and adjustments, significantly accelerating the product development cycle. By allowing designers and engineers to quickly evaluate and refine their concepts, SLA streamlines the process from initial design to final product, enhancing both efficiency and innovation.

| SLA by the Numbers |

|---|

| Max Build Size: 2100 x 700 x 800 mm Lead Times: Starting at 7 days Minimum Wall Thickness: 0.7 mm (depending on material and geometry) Dimensional Accuracy: +/- 0.2%, minimum of 0.2 mm |

Popular SLA Finishes

UV-resistant painted

Protect your SLA prints from the damaging effects of the sun while adding a layer of visual appeal with UV resistant painting. This ensures prints retain their vibrant colors and structural integrity over time.

Painted

Initially, a primer is applied to establish a smooth, even base. Subsequently, various colours are added along with intricate details, creating visually striking and customised prints.

Polished

By employing meticulous buffing and smoothing techniques, SLA parts are enhanced to achieve a glossy, reflective surface that accentuates the fine details of the print while providing excellent transparency.

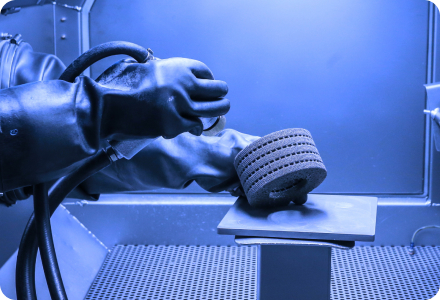

Blasted

Fine particles, such as sand or glass beads, are used to gently abrade the outer layer of the print, resulting in a smooth and uniform surface. This process is particularly effective for eliminating traces of support structures and enhancing the overall finish of the print.

Source Industrial-Grade SLA Parts

D2PCNC offers unparalleled flexibility for sourcing parts to meet your specific needs. Obtain instant quotes and place orders swiftly through our on-demand manufacturing services. For complex projects, our team of experts will collaborate closely with you to create, align, and oversee a comprehensive manufacturing quality plan from inception to completion.

On-Demand Manufacturing

- Instant quoting and DFM checks

- Short lead times

- Fast and intuitive order placement

Production Orders

- Expert support from end-to-end

- Comprehensive manufacturing and quality plan

- Guaranteed quality meeting advanced specifications

Available SLA Materials

Not sure which material is best for your project? Use our interactive technology and material advisor to explore and find the ideal solution tailored to your needs.

| SLA by the Numbers |

|---|

| Standard Resin: Standard resin strikes a fine balance between detail and cost, making it versatile for various applications. It provides a smooth surface finish and high resolution, making it ideal for prototypes and models. Commonly used for prototypes, educational models, and visual aids where detail and finish are essential. Black Resin: Black resin is renowned for its deep colour and high resolution, making it perfect for showcasing intricate details without the need for additional painting. It offers excellent dimensional accuracy and is ideal for small components in engineering and any application requiring fine details. Functional Resin: Functional resins are engineered to deliver specific mechanical properties such as high strength and stiffness, effectively simulating the performance of engineering plastics. These resins are ideal for creating functional prototypes and mechanical parts where durability and reliability are essential. High-Detail Resin: High-detail resin excels in producing intricate designs with ultra-fine features and a smooth surface finish, offering exceptional precision and detail. It is ideal for applications where minute details are crucial, such as microfluidics, detailed models, and any scenario requiring high-level accuracy. High-Temperature Resin: High-temperature resins are designed to endure elevated thermal environments while maintaining dimensional stability and mechanical properties. These resins are ideal for applications requiring heat resistance, such as fixtures exposed to high temperatures, mold prototypes, and components subjected to thermal testing. Tough Resin: Tough resins are engineered to replicate the strength and stiffness of ABS plastic, providing high-impact resistance and durability for robust prototypes and assemblies. These resins are ideal for applications such as snap-fit assemblies, rugged prototypes, and mechanical parts where durability and resilience are essential. Transparent Resin: This resin offers excellent clarity and light transmission, coupled with a smooth finish, making it ideal for prototypes requiring visible internal geometries or effective light passage. It is particularly well-suited for applications where transparency is crucial, such as lenses, fluidic systems, and lighting enclosures. |