CNC turning is a precise machining process ideal for creating cylindrical parts such as shafts and sleeves, with lead times starting at just six days.

A pre-programmed computer controls the cutting tool, ensuring high accuracy and enabling the production of both simple and intricate parts. Additionally, CNC turning is compatible with a wide range of materials, including various polymers and metals, making it a versatile choice for diverse applications.

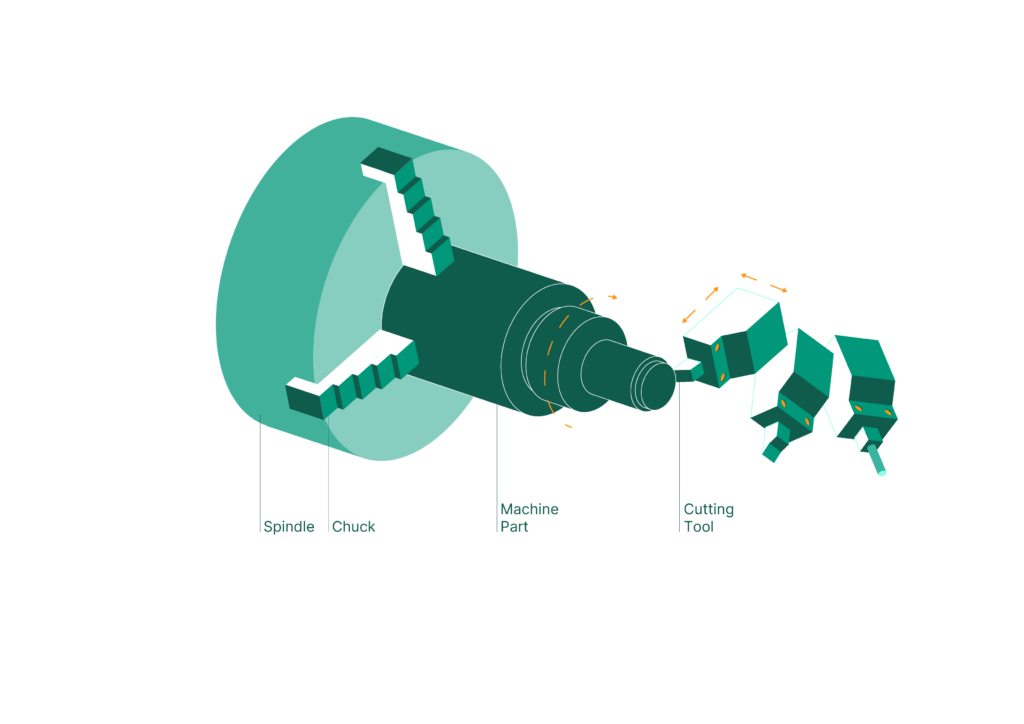

How CNC Turning Works

Turning, also known as lathing, is a subtractive manufacturing process similar to milling. However, in turning, the workpiece rotates while a stationary cutting tool with a geometrically determined edge shapes it. This rotation allows for precise removal of material to create cylindrical parts.

In addition to the rotational movement of the workpiece, the cutting tool can move horizontally. This combination of movements enables the creation of complex geometries and detailed features on the workpiece, making turning an essential process for producing high-precision components.

CNC Turning Use Cases

Turning is particularly advantageous for creating centrally symmetric parts, such as those with conical ends. This process ensures high accuracy and excellent surface finishes, leading to consistent repeatability and relatively short lead times.

| CNC Turning by the Numbers |

|---|

| Max Build Size: 400 x 1000 mm (Standard Size) Lead Times: Starting at 6 days Minimum Wall Thickness: 0.2 mm (depending on material and geometry) Dimensional Accuracy: ISO 286 Tolerance grade 7 (0.015 mm for a 6mm diameter) |

Key Feature: Diverse Range of Materials

CNC milling accommodates a wide range of materials, including metals and polymers, each offering unique properties such as strength, durability, heat resistance, and electrical conductivity. These materials can be tailored to meet specific application requirements.

This versatility allows you to select the most cost-effective material for your projects, ensuring optimal performance without compromising budget.