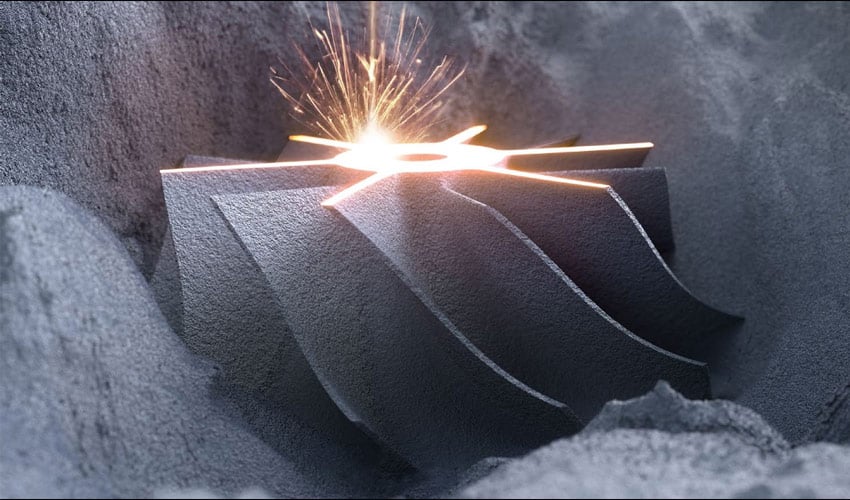

Laser powder bed fusion (LPBF) is a premier additive manufacturing technology for metals, renowned for its precision and capability to produce highly complex and dimensionally stable parts. This process involves selectively melting metal powder layer by layer using a high-powered laser, which allows for intricate geometries and fine details to be achieved with remarkable accuracy.

At D2PCNC, we leverage the advanced capabilities of LPBF to deliver high-quality metal components tailored to your specific needs. Our expertise in this technology ensures that each part is produced with exceptional detail and structural integrity, meeting the highest standards of performance and reliability. Whether you’re seeking intricate designs or robust, functional parts, D2PCNC is equipped to bring your vision to life with precision and efficiency.

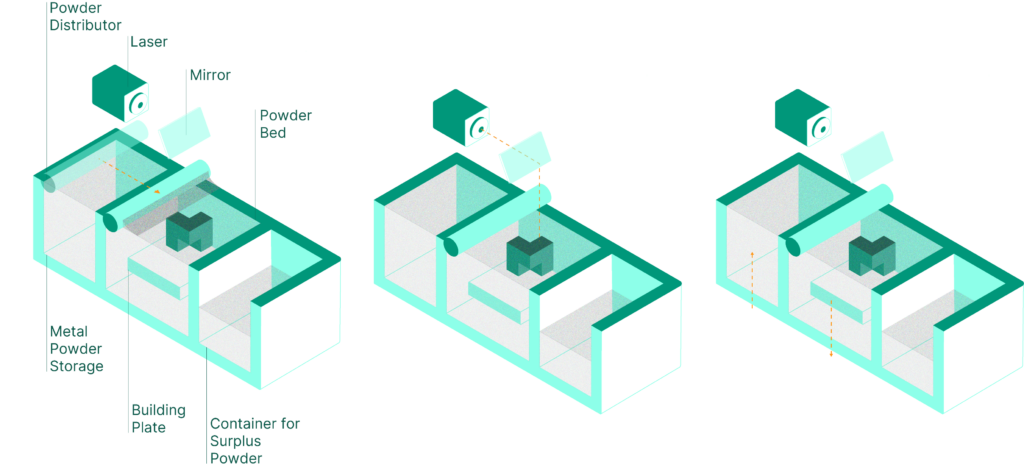

How LPBF works

Laser Powder Bed Fusion (LPBF), also known as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS), is a cutting-edge additive manufacturing technology used for producing metal parts. This process takes place in an inert gas atmosphere, where a high-powered laser selectively melts metal powder stored in a powder bed. The laser meticulously melts and fuses the powder layer by layer on the build platform, gradually building up the part with high precision.

As each layer of powder is melted and fused, support structures are used to enable the creation of intricate and complex geometries that are challenging or impossible to achieve with traditional subtractive manufacturing methods. This capability allows for greater design flexibility and innovation in metal part production.

Additionally, LPBF offers significant cost advantages by eliminating the need for additional tooling and setup. The process is also environmentally friendly, as any unused powder can be recycled and reused in future builds, further enhancing its efficiency and sustainability.

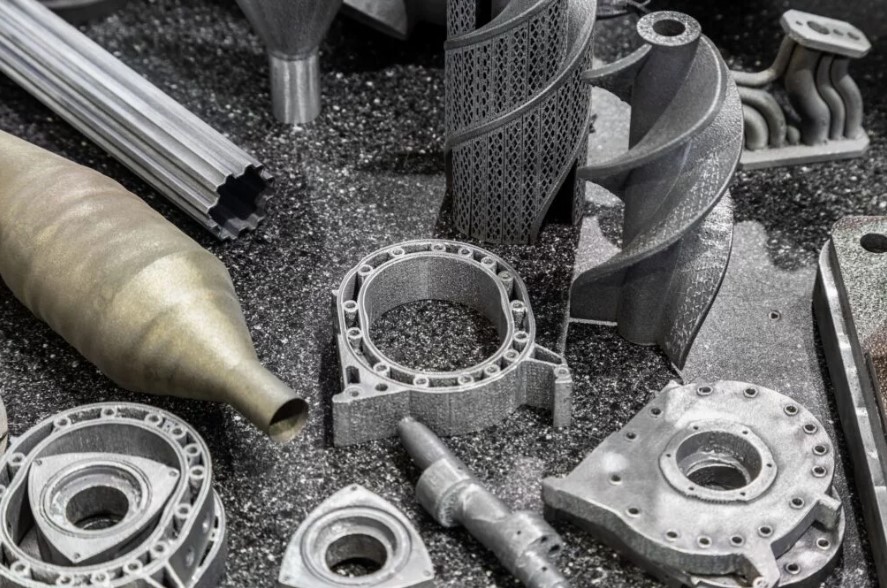

LPBF Use Cases

As a leading technology in metal additive manufacturing, Laser Powder Bed Fusion (LPBF) is widely adopted across various industries on the D2PCNC platform, including automotive, energy, aerospace, and more. Its versatility makes it ideal for both functional prototypes and engineered end-use parts, catering to a broad range of applications that demand precision and durability.

LPBF excels in producing complex, high-performance components with intricate geometries and excellent mechanical properties. Whether you need to test new designs with detailed prototypes or produce final parts that meet rigorous engineering standards, LPBF offers a reliable and efficient solution to meet your manufacturing needs.

| LPBF by the Numbers |

|---|

| Max Build Size: 500 mm x 500 mm x 500 mm (Standard) Lead Times: Starting at 12 days Minimum Wall Thickness: 0.8 mm (depending on geometry) Dimensional Accuracy: +/- 0.3% with a minimum of 0.3 mm |

Available LPBF finishes

Heat Treated

Once the material reaches and maintains a predetermined temperature, it is then gradually cooled down. This controlled cooling process allows for the precise adjustment of the material’s properties, tailoring them to meet specific requirements and enhancing performance for individual use cases.

Painted

Additional colour is often applied to the printed part using a professional spray-painting system. To achieve the best results, the part is first meticulously prepared, which includes thorough cleaning and the application of a clear coat. This preparation ensures that the paint adheres properly and the final finish meets the desired quality and appearance standards.

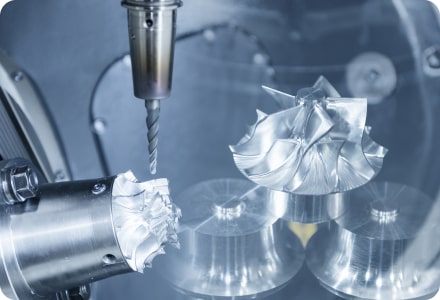

CNC Machined

Post-processing CNC options encompass turning, milling, drilling, and various other techniques. These methods offer significant advantages, including enhanced dimensional stability, reduced surface roughness, and the flexibility to meet specific customer requirements. This level of precision and adaptability ensures that the final product aligns perfectly with design specifications and performance standards.

Polished

An abrasive is employed to smooth the surface of a part by progressively working through different stages with abrasives of decreasing roughness. This iterative process gradually refines the surface, resulting in a smooth and polished finish that enhances both the part’s appearance and functionality.

Tumbled

Parts are reworked using grinding media in a container, where they undergo deburring, fine grinding, and polishing. This is achieved through the vibration or rotation of the container, which ensures that the parts are uniformly processed to achieve a smooth and refined finish.

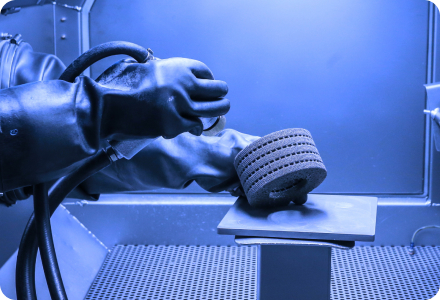

Blasted

An abrasive medium is applied to the component under high pressure to achieve precise finishing. Depending on the type of medium used—such as corundum, sand, or glass beads—both functional and optical enhancements can be achieved. This process allows for achieving specific surface roughness for functional purposes or polishing the surface to enhance its appearance, ensuring that the component meets both performance and aesthetic standards.

Source Industrial-Grade LPBF parts

D2PCNC offers flexible solutions for sourcing parts tailored to your needs. With fast quotes and on-demand manufacturing, you can quickly order parts with ease. For large or complex orders, our team of experts collaborates with you to develop, align, and oversee a comprehensive manufacturing quality plan, ensuring your project is expertly managed from start to finish.

On-Demand Manufacturing

- Instant quoting and DFM checks

- Short lead times

- Fast and intuitive order placement

Production Orders

- Expert support from end-to-end

- Comprehensive manufacturing and quality plan

- Guaranteed quality meeting advanced specifications

Available LPBF materials

Not sure which material is best for your project? Use our interactive technology and material advisor to explore and find the ideal solution tailored to your needs.

| Available LPBF materials |

|---|

| Aluminium AlSi10Mg: AlSi10Mg is an aluminium alloy known for its excellent balance of strength, hardness, and dynamic properties, along with good thermal and electrical conductivity. Its corrosion resistance makes it suitable for printed parts in wet environments. This alloy is frequently used in housing applications, functional prototypes with complex geometries, heat exchangers due to its thermal conductivity, and lightweight components such as brackets. The lead time for this material is 12 days. Copper Alloy CuNi2SiCr: Copper (Cu) is a highly flexible material with excellent electrical and thermal conductivity, and it is resistant to corrosion. The CuNi2SiCr alloy enhances these properties with added nickel and silicon, offering superior thermal and electrical conductivity, good rigidity, and improved corrosion resistance for harsh conditions. It is ideal for electrical engineering parts, tooling, and welding applications. Lead time is 15 days. Copper Alloy CuCrZr: This copper alloy provides a superb blend of electrical and thermal conductivity with strong mechanical properties, making it widely used in industries. CuCrZr is commonly employed for molds and cooling inserts in metal casting, electrodes, welding technology, and current-carrying parts like induction coils. The lead time for this material is 15 days. Copper CuCP: Copper (Cu) is highly versatile with exceptional electrical and thermal conductivity—up to ten times higher than many steels—and strong corrosion resistance. CuCp, a high-purity copper with over 99.95% copper content, is ideal for applications requiring high conductivity, such as electrical motors, inductors, and heat exchangers. It’s also used for prototypes and in the marine industry due to its durability. The lead time for CuCp is 15 days. Hastelloy X: Hastelloy X is a nickel-based alloy with chromium, iron, and molybdenum, offering excellent oxidation resistance, high-temperature strength, and good ductility for easy fabrication. It is primarily used in turbine engines for components like combustor cans and tailpipes, and is also suitable for industrial furnaces, chemical processing, petrochemical industries, and nuclear reactors. The lead time for Hastelloy X is 15 days. Inconel 625: Inconel 625 (IN625) is a nickel-based alloy renowned for its exceptional performance in high-temperature environments and resistance to oxidation, thanks to its high chromium and low iron content. This alloy is particularly well-suited for harsh chemical environments and seawater, making it ideal for the chemical processing industry, waste management, and marine applications. IN625 is commonly used in jet engine components, valves, turbine shroud rings, flare stacks, and heat exchangers. The lead time for IN625 is 15 days. Inconel 718: Inconel 718 (IN718) is a nickel-based superalloy known for its exceptional performance in high-temperature environments, maintaining strong mechanical properties up to 700 °C. It offers excellent oxidation and corrosion resistance, making it suitable for demanding applications. IN718 is commonly used in aerospace and energy industries for gas turbine parts, exhaust components, and in the chemical industry, particularly for oil industry pipes and valves. The lead time for IN718 is 15 days. Scalmalloy AlMgSc: Scalmalloy is a high-performance aluminum-magnesium alloy with added scandium, providing exceptional tensile strength and low density comparable to titanium alloys. It boasts excellent corrosion resistance, electrical conductivity, and is FIA-approved. Ideal for lightweight engineering, Scalmalloy is used in structural components for aircraft and high-performance cars, as well as in robotics, semiconductor machinery, and high-quality prototypes. The lead time for Scalmalloy is 15 days. Stainless Steel 17-4PH (1.4542): 17-4 PH stainless steel offers high yield strength and good corrosion resistance, with the ability to be heat-treated to a hardness of 34 HRC and a tensile strength 95% of that of forged material. It can be welded using TIG or electric arc welding processes. This versatile steel is ideal for producing high-strength, robust parts used in various industrial applications. The lead time for 17-4 PH is 15 days. Stainless Steel 316L (1.4404): 316L stainless steel is known for its excellent corrosion resistance, making it ideal for parts used in moist environments. It offers good machinability for re-working and enhancements, and has high ductility. This versatile material is used across aerospace, automotive, food, and energy industries, as well as for components like pipes and valves in the chemical industry, and in wristwatch cases and bracelets. The lead time for 316L is 15 days. Titanium Ti6AI4V: Titanium is valued for its high strength-to-weight ratio, excellent corrosion resistance, and oxidation resistance, making it a versatile material for various industries. It is particularly suited for medical and dental applications due to its biocompatibility. Additionally, its strength and low weight make it ideal for high-performance parts in racing cars and bionic brackets in aviation. The lead time for titanium is 15 days. Tooling Steel MS1 (1.2709): Tooling steel 1.2709, also known as MS1, is notable for its high tensile strength and toughness, maintaining stable mechanical properties up to around 400°C. It can be further enhanced through heat treatment and martensitic hardening. This steel is used for tooling inserts in injection molding, extrusion tool inserts, functional prototypes, and fixtures. Its high strength makes it suitable for motor sports and aviation applications. The lead time for 1.2709 is 15 days. |