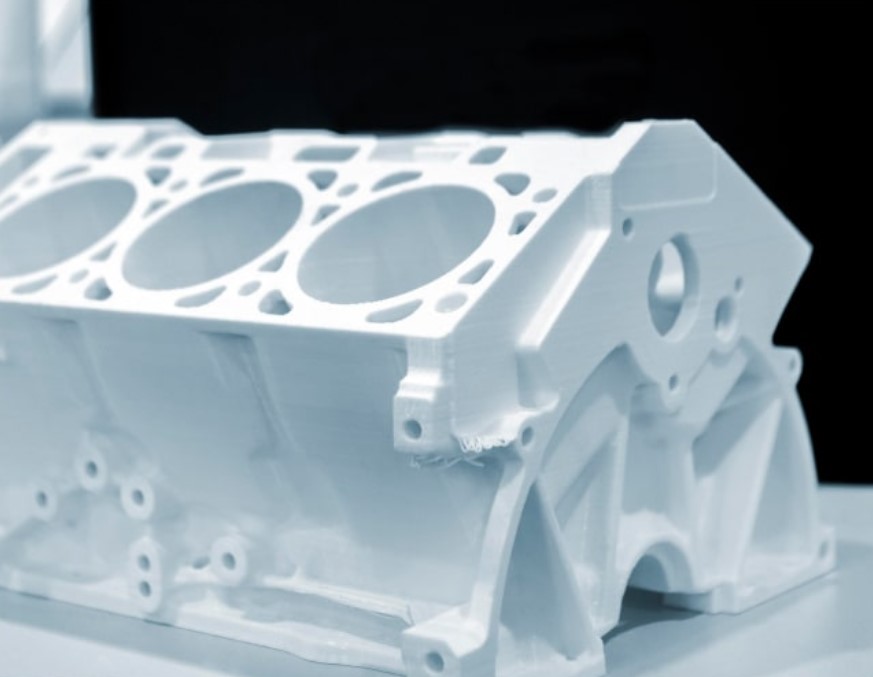

Selective Laser Sintering (SLS) excels in producing complex polymer parts with exceptional accuracy, making it a preferred 3D printing method for both prototyping and end-use components.

One of the key benefits of SLS is its elimination of the need for additional tooling, which reduces both setup costs and time. The process is also resistant to tooling wear and tear, ensuring consistent performance and quality over multiple production cycles. Additionally, SLS is a cost-effective solution that delivers high-value results for a wide range of applications.

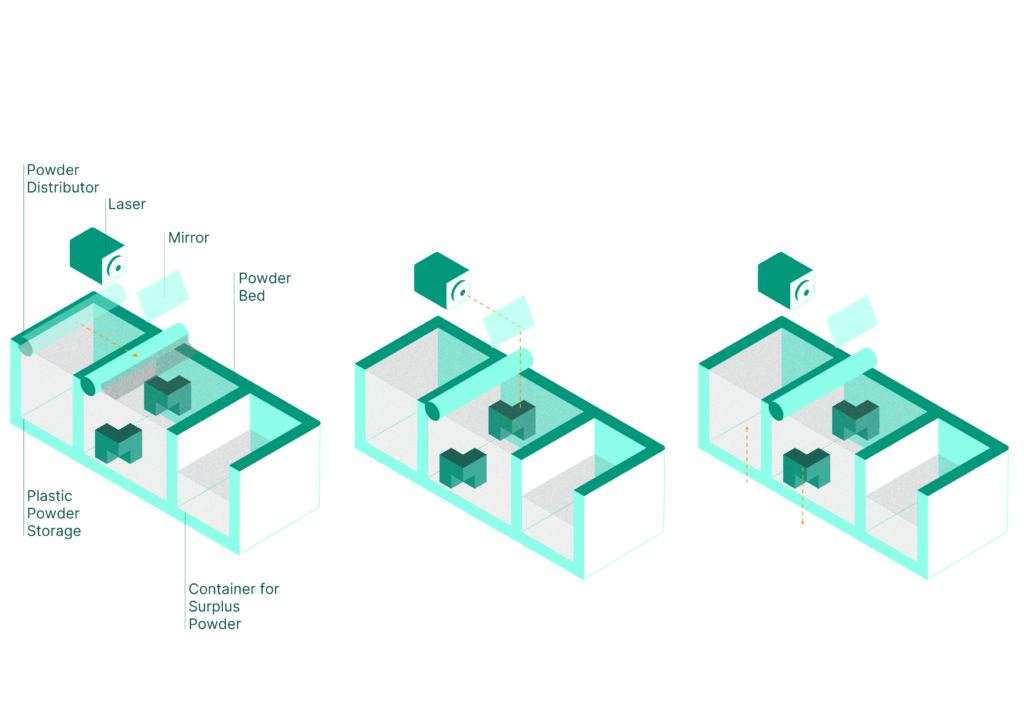

How SLS works

Selective Laser Sintering (SLS) is a versatile powder-based additive manufacturing technology, distinct from Laser Powder Bed Fusion (L-PBF) in that it uses plastic powders rather than metals. SLS builds parts layer by layer from a 3D model, leveraging a powder bed that supports the precise construction of complex shapes with high accuracy.

In the SLS process, the plastic powder is heated just below its melting point, enabling the material to maintain a fine, powdery consistency. The laser selectively sinters the powder by applying thermal energy, which fuses the particles together to form the desired part with detailed precision.

This method allows for the production of durable and functional components with excellent mechanical properties. The ability to create intricate designs and complex geometries makes SLS a popular choice for rapid prototyping and end-use applications, catering to a wide range of industrial needs.

SLS Use Cases

SLS, or Selective Laser Sintering, is a widely used additive manufacturing technology available on the D2PCNC platform, renowned for its ability to produce high-quality plastic parts quickly. This technology excels in creating both rapid prototypes and end-use components, making it a versatile choice for various applications.

SLS is especially valued for its ability to deliver robust mechanical properties in printed parts, which is crucial for many practical uses. It is particularly effective for producing parts that need to withstand functional demands, such as jigs, fixtures, and replacement components, thanks to its efficient production process.

Additionally, SLS supports a range of materials, including those with enhanced strength and durability. This makes it an ideal solution for manufacturing parts that require high performance and reliability, meeting the needs of diverse industries from automotive to aerospace.

| SLS by the Numbers |

|---|

| Max Build Size: Ranging from 340 X 340 X 600 mm to 700 X 380 X 580 mm (material dependent) Lead Times: Starting at 7 days Minimum Wall Thickness: 0.8 mm (material/geometry dependent) Standard Color: White Dimensional Accuracy: +/- 0.3% with a minimum of 0.3 mm |

Popular SLS Finishes

Smoothed

During the smoothing process, a chemical reaction is employed to refine the surface of the plastic component. The component is immersed in a solution bath where a specialized medium dissolves the top layer. This meticulous process effectively removes surface imperfections, resulting in a significantly smoother and more refined finish.

Painted

Additional colour is applied to the printed part using a professional spray painting system. Prior to painting, the part undergoes meticulous cleaning to remove any debris or contaminants. A clear coat is then applied to enhance durability and ensure a high-quality, finished appearance.

Tumbled

Parts are reworked using grinding media within a container, where they undergo deburring, fine grinding, and polishing through the vibration or rotation of the container. This process ensures a smooth, refined surface finish.

Color dyed

The plastic component is immersed in a water bath. The resulting chemical reaction causes the dye to penetrate the part.

Sealed

The sealing process uses an aqueous solution to close the outer surface or skin of the part and fill in tiny pores. The sealing solution is manually applied or dipped depending on the part’s geometry.

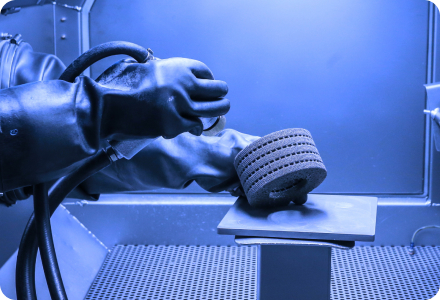

Blasted

An abrasive medium is applied to the component under high pressure. By using different media (e.g., corundum, sand, or glass beads), both functional (achieving a specific surface roughness) and optical (polishing the surface) finishing can be performed.

Key Feature: Diverse Materials

SLS materials cater to a diverse range of applications. For robust performance, aluminum and glass-filled PA 12 deliver exceptional strength. Other materials offer biocompatibility, making them ideal for medical applications. Additionally, SLS can produce flame-retardant parts that meet stringent certification standards for industries like aerospace, rail, and electronics.

Source Industrial-Grade SLS parts

D2PCNC offers flexible solutions for sourcing parts tailored to your needs. With fast quotes and on-demand manufacturing, you can quickly order parts with ease. For large or complex orders, our team of experts collaborates with you to develop, align, and oversee a comprehensive manufacturing quality plan, ensuring your project is expertly managed from start to finish.

On-Demand Manufacturing

- Instant quoting and DFM checks

- Short lead times

- Fast and intuitive order placement

Production Orders

- Expert support from end-to-end

- Comprehensive manufacturing and quality plan

- Guaranteed quality meeting advanced specifications

Available SLS Materials

What’s the best material for your project? Discover the ideal choice with our Interactive Technology and Material Advisor. Explore your options today!

| Available SLS Materials |

|---|

| PA 11: PA 11 is a bio-based polymer known for its excellent mechanical properties, high ductility, and impact strength, making it suitable for functional parts across various industries, including automotive. Its ability to be dyed and its biocompatibility make it increasingly popular in orthotics for custom and small-series parts. Typical applications for PA 11 include automotive interior parts, prosthetics, orthotics, and functional prototypes. The lead time for PA 11 is 7 days. PA 12: PA 12 is a polyamide (PA) and a standard material for Selective Laser Sintering (SLS), known for its high strength and long-term stability. It offers excellent chemical resistance and biocompatibility, making it a popular choice in the medical industry. PA 12 is commonly used for fully functional prototypes and end-use parts, particularly in the orthopedic sector due to its biocompatibility. The lead time for PA 12 is 7 days. PA 12 Glass filled (GF): PA 12 GF is a polyamide reinforced with glass beads, which enhances its long-term durability and allows it to withstand high thermal loads. This material combines high density with excellent tensile strength. PA 12 GF is commonly used for fully functional prototypes and end-use parts, particularly in the automotive industry, where it can endure high-temperature environments. The lead time for PA 12 GF is 9 days. PA 12 Al-filled: PA 12 Al-filled is a polyamide infused with aluminum, giving it a metallic appearance and excellent dimensional stability at high temperatures. This material combines the lightweight nature of plastic with enhanced thermal performance and can be further customised through grinding, polishing, or coating. PA 12 Al-filled is commonly used for fully functional prototypes, jigs and fixtures, and components requiring high-temperature and high-stress resistance. The lead time for PA 12 Al-filled is 9 days. PA 12 Flame Retardant (FR): PA 12 FR is a polyamide enhanced with a flame retardant, making it ideal for industries requiring strict safety or regulatory compliance. It combines high tensile strength with effective flame resistance. This material is approved for aerospace applications, commonly used in aircraft interior components, and is also employed in passive electronic parts. The lead time for PA 12 FR is 9 days. |